Base oil is an oil that is considered as a base for other lubricants. After adding additives to the base oil, the final lubricant is obtained. Base oils are the most important components of lubricants in terms of volume, and in terms of weight, on average, they make up more than 95% of the formulation of a roller.

Most of the base oil consumed in the world today is obtained from crude oil refining. Since most of the base oil used in the production of lubricants is obtained from petroleum sources, the base oil industry is considered as a part of the petroleum industry. The characteristics of the base oil obtained from the oil depend on the type of crude oil and the refining process. Petroleum base oils inherit their chemical components, both favorable and unfavorable, from the crude oil obtained during the refining process. Since crude oil contains various compounds such as paraffinic, naphthenic, aromatic hydrocarbons, as well as sulfur compounds, base oils are also composed of these compounds. The main components of petroleum-based oils, which also affect the properties of the oil, are paraffinic, naphthenic and aromatic compounds.

Solvent strength: engine cleaning, sealant compatibility, process applications and formulation stability.

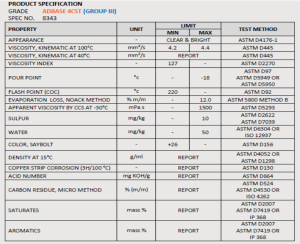

The main uses and applications of SN350 base oil:

– Production of gasoline and diesel engine oils, dual fuel

-Production of all types of marine diesel engine grease and gear oil

– Types of hydraulics, turbines, milling operations and other industrial lubricants Specification Of Virgin Base Oil SN350

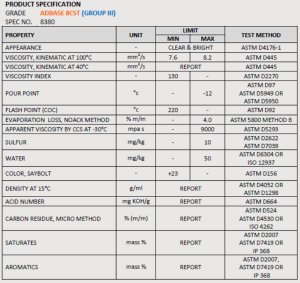

SN 500 base oil is defined as a light base oil at the high end of the Grade 1 base oil specification. It is mostly used in the production of lubricants. This is a Group I base oil that has gone through the stages of solvent purification and wax removal. To complete the refinement, the hydrogen was purged to remove any impurities. This oil is for lubricant formulations and mixers for commercial and passenger vehicles as well as industrial applications. This oil does not have any impurities or compounds that can negatively affect the quality of the oil. This oil is usually composed of conventional petroleum base oils. SN 500 base oil acts as a base for several industrial lubricants:

-engine oil

– Transmission fluids Gear oils

– Metalworking fluids

– The greases

-Hydraulic oils

-Transformer oils

The advantages of SN500 base oil are:

– Stability of characteristics during operation

-light color

– Optimal oxidation and thermal stability

– little escape Excellent viscosity stability

– Appropriate viscosity index

-High flash point

– TAN down

– Low amount of sulfur

PRO

All material and intellectual rights of this site belong to See Star Energy Company.