Polypropylene, abbreviated PP, is one of the materials used in the packaging industry, and only 3 to 5 percent of it is recycled in the United States, and most of it ends up in landfills. Recycled PP is seen in gray or black, which is not suitable for packaging at all. Anyway, recycled PP is used to make car parts, park benches, speed bumps, etc.

Polypropylene granules or pp, as the second most used polymer in the world, includes two groups of homopolymers and copolymers. The most applicants for PP homopolymer granules are textile industries, cellophane manufacturers, injection, sack weaving and sheets. The wastes that produce this granule include all kinds of belts, sacks, and jhanbo….

PP co-polymer granule has more specialized applications than PP homo-polymer. Because it has better physical and mechanical properties. Therefore, its price is higher. This granule is produced from scraps of car bumpers and batteries.

Having said that, the target market of this granule will be companders as well as industrial parts manufacturers.

Recycled Polypropylene Granules

Polypropylene, abbreviated PP, is one of the materials used in the packaging industry, and only 3 to 5 percent of it is recycled in the United States, and most of it ends up in landfills. Recycled PP is seen in gray or black, which is not suitable for packaging at all. Anyway, recycled PP is used to make car parts, park benches, speed bumps, etc.

- Description

- Battery PP Copolymer

- Transparent PP Copolymer

- PP copolymer white pipe

- Glass Fiber Reinforced PP

- Jumbobag PP

- Recycled from PP sacks

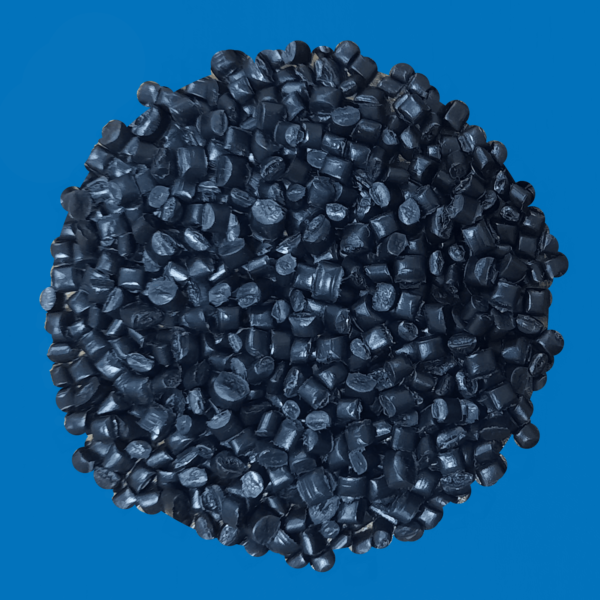

Produced from the scraps of first-hand battery shells that have been ground and washed to remove any impurities.

Extruded with mechanized equipment and using an 80 mesh filter to achieve the highest quality in the final product.

Mix and homogenize to achieve the same properties in all parts of the product.

| Qualitative parameter | Unit | Evaluation method | Quantity |

| Melt flow index | gr/10 min | ASTM D1238(230C°/2.16Kgr) | 9±1 |

| Ash percentage | % | ASTM D5630(800C°/15min) | 1> |

Recycled from clear containers and IML made of polypropylene that has been washed and ground to completely remove impurities.

Extruded in the most accurate and appropriate process along with two stages of filtration to achieve the best quality.

Mix and homogenize to achieve the same properties in all parts of the product

| Qualitative parameter | Unit | Evaluation method | Quantity |

| Melt flow index | gr/10 min | ASTM D1238(230C°/2.16Kgr) | 16±1 |

| Ash percentage | % | ASTM D5630(800C°/15min) | 4±1 |

Granule recycled from white pipes of domestic water supply.

Milled and washed to completely remove impurities and dirt.

Extruded in the most accurate and appropriate process to achieve the best quality without loss of properties.

Mix and homogenize to achieve the same properties in all parts of the product.

| Qualitative parameter | Unit | Evaluation method | Quantity |

| Melt flow index | gr/10 min | ASTM D1238(230C°/2.16Kgr) | 0.5±0.05 |

| Ash percentage | % | ASTM D5630(800C°/15min) | 1≥ |

Produced from recycled polypropylene homopolymer and reinforced with 30% glass fibers.

Excellent mechanical properties and processability.

Suitable for the production of injection parts in the automotive, electronic and home appliance industries.

Black color

| Qualitative parameter | Unit | Evaluation method | Quantity |

| Melt flow index | gr/10 min | ASTM D1238(230C°/2.16Kgr) | 5±1 |

| Ash percentage | % | ASTM D5630(800C°/15min) | 30±1 |

Recycled from polypropylene jumbo bags.

Milled and washed to completely remove impurities and dirt.

Extruded in the most accurate and appropriate process to achieve the best quality.

Mix and homogenize to achieve the same properties in all parts of the product.

It has a small percentage of polyethylene.

| Qualitative parameter | Unit | Evaluation method | Quantity |

| Melt flow index | gr/10 min | ASTM D1238(230C°/2.16Kgr) | 9±1 |

| Ash percentage | % | ASTM D5630(800C°/15min) | 5±1 |

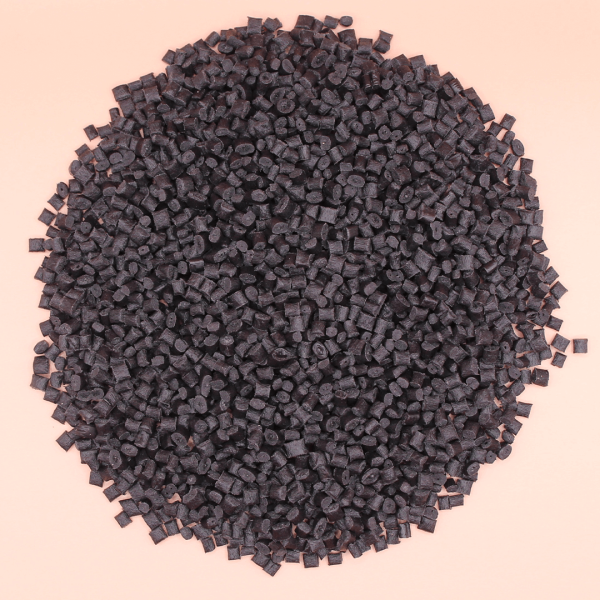

Recycled from polypropylene sacks

Milled and washed to completely remove impurities and dirt.

Extruded in the most accurate and appropriate process to achieve the best quality.

Mix and homogenize to achieve the same properties in all parts of the product.

Excellent coloring due to the bright color of the product.

| Qualitative parameter | Unit | Evaluation method | Quantity |

| Melt flow index | gr/10 min | ASTM D1238(230C°/2.16Kgr) | 11±1 |

| Ash percentage | % | ASTM D5630(800C°/15min) | 6±1 |

All material and intellectual rights of this site belong to See Star Energy Company.